Behind every iconic building in Dubai, there’s a blueprint you’ll never see. It’s not for the steel and glass, but for its survival. This is the heart of risk management in construction projects: a strategic playbook that guides a project through the inevitable storms of budget fluctuations, supply chain chaos, and regulatory mazes. It’s what separates a project that thrives from one that stalls under pressure.

Why Risk Management Is the True Foundation of Success

Picture a construction project as a high-stakes expedition. You’ve got the map (your architectural plans), a skilled crew, and a clear destination (project completion). But the journey ahead is full of potential obstacles—sudden storms like economic shifts, treacherous terrain like unforeseen site conditions, and logistical headaches like supply chain delays. A smart expedition leader doesn't just hope for clear skies; they anticipate these challenges and have a plan for them.

That’s exactly what risk management does. It’s the proactive work of identifying, assessing, and defusing threats before they can blow up into full-blown crises. It's not about making a project risk-free, because that’s simply not possible. It's about turning potential disasters into manageable challenges, making it a powerful driver of profitability and predictability in Dubai's high-pressure construction scene.

The Unique Challenges in Dubai and the UAE

The construction industry here in the United Arab Emirates (UAE) operates in a complex risk environment, shaped by factors you won’t find just anywhere. Research breaks these risks down across political, economic, legal, and financial categories, showing that construction firms often grapple with medium to high-risk levels from economic volatility and regional instability. For a much deeper dive, you can review the full study of risks in the MENA construction sector.

This environment demands a specialised approach, not a generic checklist. At Freeline Engineering Consultants (FEC), we know that managing risk effectively in Dubai means going deeper. It requires:

- Deep Local Knowledge: Understanding the subtleties of municipal approvals, utility connections, and the local supply chains is non-negotiable. Our team has spent nearly three decades mastering this landscape.

- Proactive Strategy: We have to move beyond just reacting to problems and actively anticipate market shifts and regulatory updates. This foresight is built into our project management DNA.

- Integrated Expertise: You need to combine architectural, engineering, and project management perspectives to see the entire board, not just the individual pieces. Our in-house, multi-disciplinary team provides this holistic view.

For any developer or investor, a solid risk management plan isn’t an expense; it’s the ultimate insurance policy for your project's timeline, budget, and reputation. It gives you the confidence to build boldly in a market that's always in motion.

At FEC, we partner with you to build this essential blueprint for success. Our approach is built on nearly three decades of hands-on experience navigating the specific challenges of the Dubai market. We don’t just flag problems; we engineer solutions that protect your investment and secure your project’s success right from day one.

Contact us today to discuss how we can bring this level of certainty to your next project.

Mapping Common Construction Risks in Dubai

To get a handle on risk, you first have to understand the unique landscape where your project lives. In Dubai, the challenges are anything but generic. For projects like luxury villa complexes, mid-rise residential buildings, and commercial centres, the risks are specific, interconnected, and tied directly to the region's dynamic environment.

Think of it like navigating the Dubai Creek. An outsider might just see water, but a local dhow captain knows the hidden sandbars and the shifting currents. Successful risk management in construction projects here demands that same level of intimate, local knowledge.

At Freeline Engineering Consultants (FEC), we don’t use generic checklists. We map the real, on-the-ground risks that can impact your investment, focusing on the challenges unique to Dubai's market.

Here’s a look at some of the most common risks we see in our projects and how they can play out.

Common Construction Risks in Dubai Projects

| Risk Category | Specific Risk Example | Potential Impact |

|---|---|---|

| Financial & Market | Sudden increases in global steel or cement prices | Budget overruns, eroded profit margins, project financing issues. |

| Supply Chain | Delays at Jebel Ali Port or unexpected import tariffs | Project timeline extensions, material shortages, increased costs. |

| Labour & HR | Shortage of specialised welders or certified electricians | Delays in critical path activities, potential quality compromises, higher labour costs. |

| Operational | Unforeseen ground conditions (e.g., sabkha) during excavation | Foundation redesign, schedule delays, unexpected dewatering costs. |

| Technical & Design | Poor coordination between MEP and structural plans | On-site clashes and rework, wasted materials, construction delays. |

| Regulatory & Legal | Delays in securing NOCs from multiple authorities (DEWA, RTA, DM) | Project start delays, fines for non-compliance, costly work stoppages. |

| Contractual | Ambiguous scope of work clauses in the main contract | Scope creep, disputes with contractors, budget overruns from change orders. |

| Environmental | Extreme summer heat impacting worker productivity and equipment | Reduced efficiency, increased safety incidents, potential for equipment failure. |

This table gives you a snapshot, but let's dive a little deeper into the three main pillars of risk we see every day.

Financial Volatility and Supply Chain Pressures

Financial instability is one of the quickest ways a project can go sideways. A spike in the global price of steel or a new tariff on finishing materials can instantly eat into your profit margins. As a global hub, Dubai feels these ripples immediately.

Imagine a mid-sized commercial building. The budget is tight, counting on material costs staying within a 5% variance. A geopolitical event overseas disrupts shipping, causing a 20% surge in the price of MEP components. Without a plan, that single event could derail the entire project.

Proactive financial risk management isn't just about having a contingency fund. It’s about building a resilient supply chain, looking at forward purchasing agreements, and keeping a close eye on market indicators to see shocks coming.

Operational and Logistical Bottlenecks

Moving from the balance sheet to the construction site, operational risks are the daily hurdles that can snowball into major delays.

Here are a few common ones in Dubai:

- Skilled Labour Shortages: Finding and keeping qualified labour for specialised tasks is a constant challenge, affecting both quality and timelines.

- Complex Logistics: Getting materials and equipment delivered in a busy city like Dubai requires meticulous planning to avoid traffic snags and a congested site.

- Unexpected Ground Conditions: Even with surveys, you can hit unforeseen soil issues when you start digging for a villa community, forcing costly redesigns of foundations.

- Equipment Failure: The harsh climate here puts a huge strain on machinery. A critical crane breaking down can bring the whole site to a halt if there's no backup plan.

Contractual and Regulatory Ambiguities

The third pillar of risk is the paperwork that holds everything together. Ambiguous clauses in contracts can quickly become battlegrounds for disputes. A poorly defined scope of work is a recipe for endless change orders and budget blowouts.

On top of that, navigating the local regulatory environment is a risk in itself. Getting approvals from various authorities is a complex dance where one small misstep can cause big delays. This is where deep local expertise is priceless—understanding the nuances of each authority's requirements is often the key to keeping a project moving forward.

At FEC, we bring this local, multi-faceted view to every project. We know these risks aren't isolated; they’re all connected. By identifying and mapping these specific threats from day one, we help turn your project's blueprint into a truly resilient plan for success.

A Proven Framework for Managing Risk

Effective risk management in construction projects isn’t about ticking boxes in a one-off meeting. It's a living, breathing process—a dynamic defence system that has to adapt as your project grows and changes. Especially in a fast-paced environment like Dubai, having a solid framework is the difference between reacting to problems and proactively owning your project’s outcomes.

At Freeline Engineering Consultants (FEC), we rely on a proven four-stage framework that methodically shields your project from the unexpected. This isn't just theory pulled from a textbook; it's a practical process we've sharpened over nearly three decades of hands-on work right here in the UAE. Let’s walk through each phase to show you how this structured approach protects your investment.

Stage 1: Risk Identification

You can't manage a risk you don't see coming. The first step, always, is to get a clear view of the entire playing field. The goal here is to create a complete list of every potential threat, no matter how small it might seem at first.

This is a team effort at FEC. We don't just sit behind spreadsheets; we run expert workshops that bring everyone to the table—architects, engineers, project managers, and even key suppliers. By pooling this collective experience, we uncover risks that one person, working alone, would almost certainly miss. We also dig into historical data from our massive portfolio of Dubai projects to spot patterns and recurring challenges specific to certain builds, like villa communities or industrial warehouses.

Stage 2: Risk Analysis

Once we have our list of potential risks, we need to figure out which ones actually matter. This is where we shift from asking "what if?" to asking "how likely?" and "how bad?" This analysis is critical because it tells us where to focus our energy and resources.

We look at each risk through two key lenses:

- Probability: What are the actual odds of this happening? A major sandstorm in Dubai is a low-probability event, but it would have a huge impact. A minor delay in a material delivery, on the other hand, might be a high-probability risk with a much smaller impact.

- Impact: If the risk does happen, how severe will the consequences be? We’re talking about financial loss, schedule delays, safety incidents, or even damage to your reputation.

By putting a value on these two factors, we can prioritise the threats that need immediate, robust response plans versus those we can simply keep an eye on.

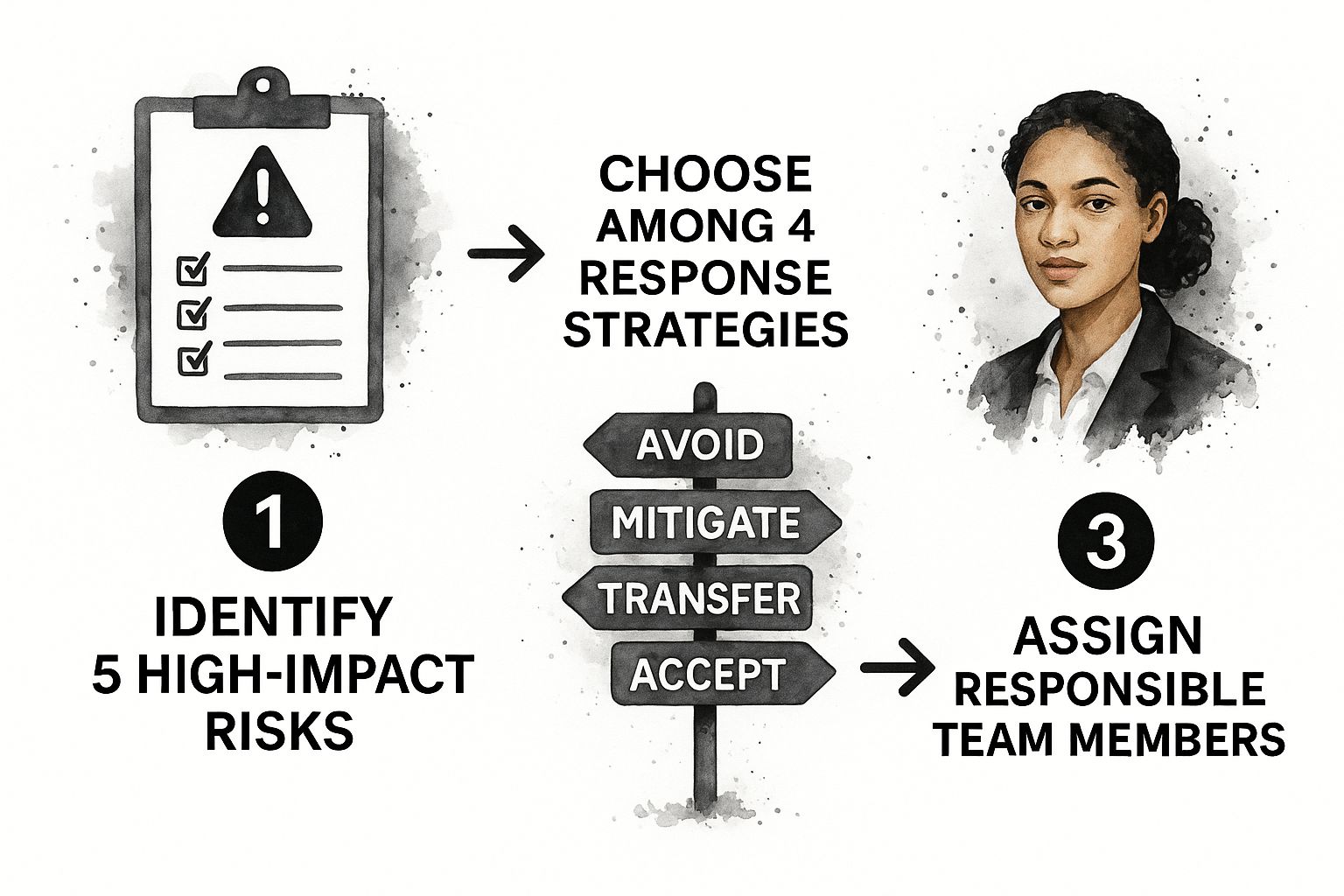

The visual below shows a simplified flow for turning these identified risks into concrete assignments for the team.

This process ensures every high-impact risk isn't just acknowledged; it's paired with a clear strategy and handed over to a specific team member who owns the response.

Stage 3: Risk Response Planning

With a prioritised list in hand, it's time to build clear, actionable strategies. The aim is to pick the most effective and efficient way to handle each threat. Generally, our responses fall into one of four buckets:

- Avoid: Sometimes the best move is to change the plan entirely to eliminate the risk. For example, if a specific imported material is facing unpredictable tariffs, we might redesign the specification to use a high-quality, locally sourced alternative instead.

- Transfer: This is about shifting the financial fallout of a risk onto a third party. The most common ways to do this are through insurance policies or by writing specific indemnity clauses into subcontractor agreements.

- Mitigate: These are the active steps we take to reduce a risk's probability or its potential impact. To counter the risk of a skilled labour shortage, we might pre-qualify several subcontractors or build extra buffer time into the schedule for the most critical tasks.

- Accept: For some low-impact risks, the smartest move is simply to accept them and have a plan to deal with the consequences if they occur. This isn't ignoring the risk; it's a conscious decision, usually backed by a contingency fund.

The response plan is your project's playbook. It ensures everyone knows exactly what to do the moment a threat starts to look real, preventing panic and allowing for swift, decisive action.

Stage 4: Risk Monitoring and Control

A risk management plan isn't a document you create once and file away. It’s a living guide that needs constant attention throughout the project’s life. Construction projects are fluid; new risks pop up, and old ones can become more or less severe over time.

This final stage is all about vigilant oversight. We track the risks we've identified, scan the horizon for new ones, and constantly check if our response strategies are working. Regular risk review meetings are a cornerstone of our project management in the construction industry, making sure the plan stays relevant from the first day on-site to the final handover. If a mitigation plan isn't performing as expected, we adjust our approach. This continuous feedback loop is what keeps your project resilient, protecting your timeline and your budget.

Navigating Dubai's Regulatory and Environmental Hurdles

In Dubai's construction world, the real race isn't always about how fast you can build, but how efficiently you can navigate the city's regulatory bodies. The critical path to finishing a project—whether it's a sleek commercial space or a sprawling villa community—runs straight through the offices of these authorities. This makes mastering the approvals process a core part of risk management in construction projects.

Think about it: even a small delay in getting a No-Objection Certificate (NOC) or a utility connection can set off a costly chain reaction. Suddenly, you have idle equipment and a full crew on-site, racking up costs without making any progress. This is where having deep, local expertise isn't just helpful; it's essential for turning a potential roadblock into just another step in the process.

At Freeline Engineering Consultants (FEC), we get it. These hurdles aren't just administrative boxes to tick; they are significant project risks. With nearly three decades of experience in Dubai, we've developed an intimate understanding of the requirements and built solid working relationships with key authorities like Dubai Municipality, DEWA, and the RTA.

The Challenge of Procedural Delays

The complex web of permits and approvals is a well-known reality of building in Dubai. Each authority has its own standards, submission portals, and review timelines, creating a layered process that demands perfect timing. One mistake can send you right back to the start, costing you precious weeks or even months.

According to the World Bank's 2020 Doing Business report, procedural delays remain a major risk factor in the UAE's construction sector. The report highlights how the sheer number of steps to legally complete a project, like a warehouse, can stretch timelines. While the UAE has made huge strides in streamlining these processes, project managers still need to plan for these administrative risks to keep schedules and budgets from spiralling.

At FEC, we don't see this as mere bureaucracy. We see it as a system that rewards precision and foresight. Our team acts as your project’s diplomatic corps, making sure every submission is right the first time and proactively engaging with authorities to keep things moving.

This proactive approach is everything. We don't just drop off paperwork and hope for the best. We anticipate questions, prepare exhaustive documentation, and keep the lines of communication wide open. To get a better sense of what this involves, take a look at our detailed guide on the Dubai Municipality approval process, which breaks down a crucial piece of this puzzle.

Environmental Risks Unique to the Region

Beyond the paperwork, Dubai's unique environment adds another layer of risk that needs careful handling. While the climate is predictable most of the year, its extremes can have a big impact on both people and materials.

We build these environmental factors into every project plan from day one:

- Extreme Heat: The intense summer temperatures can slow down workers, put a strain on equipment, and affect how materials like concrete cure. Planning for shaded work areas, adjusting work hours, and ensuring proper hydration isn't just a safety measure—it's a productivity essential.

- Unexpected Weather: It might not happen often, but sudden, heavy rain can flood sites, ruin stored materials, and block access. A solid site management plan must include contingencies for drainage and protecting sensitive goods from water damage.

- Sustainability Mandates: Dubai is pushing hard for green building codes and sustainability. If you don't bake these standards into the design from the start, you could be looking at expensive rework and approval delays down the line. We stay on top of these evolving requirements to ensure your project is compliant from the get-go.

Successfully managing both regulatory and environmental challenges takes more than just a good plan. It takes a partner with the experience and relationships to see hurdles coming and navigate them smoothly. With FEC, you get an ally committed to clearing the path for your project, making sure avoidable delays don't end up derailing your timeline or your budget.

Real-World Examples of Risk Mitigation in Action

Theory is a great starting point, but seeing how it works in the real world is what really matters. To show how a disciplined approach to risk management in construction projects isn't just a paper exercise, let's look at some real situations from our work here in Dubai.

These stories, with client details kept private, show how getting ahead of problems turns potential disasters into manageable outcomes. They follow a simple problem-action-result format, offering a clear view of how the Freeline Engineering Consultants (FEC) framework delivers genuine value on our projects.

Case Study 1: The Material Price Shock

The Problem: We were managing a mid-sized commercial development in Al Quoz, and things were running smoothly as we moved into the structural phase. The budget was tight, with steel reinforcement costs locked in based on initial supplier quotes. Suddenly, an international trade dispute caused global steel prices to rocket, and our primary supplier hit us with a 30% cost increase. This was a major shock that threatened to blow a hole in the project budget.

Our Action: Thankfully, our initial risk planning had already flagged supply chain volatility as a major threat. So, we had a backup plan ready to go. Instead of putting all our eggs in one basket, our procurement team had already vetted and built relationships with three separate steel providers in the UAE.

The moment we got the price-hike notice, we jumped into action:

- Diversification: We immediately contacted our alternative suppliers for urgent quotes.

- Negotiation: With competitive offers in hand, we went back to our main supplier. Our long-term relationship and the new market data gave us some serious leverage.

- Strategic Sourcing: We ended up splitting the order. We took a portion from the original supplier at a slightly better rate and sourced the rest from another provider with more stable pricing.

The Result: This quick, multi-pronged response completely defused the situation. We dodged the full 30% price surge, containing the final budget impact to a much more manageable 4% on that single line item. Best of all, there were no delays in material delivery, so the project timeline was unaffected. It was a perfect example of how proactive planning protects a project's financial health from market chaos.

Case Study 2: The Unforeseen Permit Delay

The Problem: We were in the home stretch on a luxury villa community in Jumeirah when we hit a wall. A new fire suppression system update required a crucial civil defence NOC, but the authority unexpectedly demanded additional schematics not in the original scope. This brought all related interior finishing work to a dead stop. The initial forecast was a six-to-eight-week delay, which meant a costly work stoppage and a blown handover date.

Our Action: We had identified regulatory delays as a key risk right from the start. Our response strategy was built on two things we know well: deep local relationships and smart, flexible scheduling. Just sitting around and waiting wasn't an option.

Our team immediately took two steps at once:

- Direct Engagement: We used our established contacts within the Dubai Civil Defence to get a face-to-face meeting and clarify exactly what they needed. This meant no guesswork.

- Rapid Redesign: Our in-house engineers got to work immediately, turning around the updated drawings in just three working days.

- Strategic Rescheduling: At the same time, the project manager shuffled the work schedule. Crews that couldn't work on interiors were moved to external landscaping, finishing boundary walls, and final utility trenching—all vital tasks that could happen independently.

The Result: The combination of clear communication and agile planning worked perfectly. We secured the updated NOC in just two weeks, not the six to eight we were originally quoted. Thanks to the smart rescheduling, there was zero downtime for our workforce, which saved a huge amount in idle site costs. The project was handed over right on schedule, protecting the client’s return on investment and proving the immense value of having experienced local experts navigating the process.

Choosing FEC as Your Strategic Risk Partner

In Dubai's fast-paced construction market, picking the right partner to manage your risk is easily one of the most important decisions you'll make for your project. This is where Freeline Engineering Consultants (FEC) really stands out. We don’t just offer advice from the sidelines; we become a core part of your team, bringing invaluable local knowledge to every single stage.

Our management framework is both transparent and proven—it’s the foundation of everything we do. We have built a solid reputation for steering even the most complex projects to a successful finish, turning the unknown into a clear, actionable strategy. It's this proactive approach to risk management in construction projects that transforms potential problems into well-managed opportunities.

A Client-Centric Partnership

At FEC, our philosophy is simple: your project goals are our goals. We are completely committed to delivering the certainty and security your investment deserves, protecting both your budget and your timeline. Our team’s deep-rooted understanding of local regulations and market dynamics gives our clients a serious advantage. We've proven time and again that our hands-on, Dubai-specific expertise is the key to mitigating risks before they become crises.

Choosing a partner for risk management is about entrusting them with your vision. We honour that trust by applying nearly three decades of dedicated Dubai experience to protect your project and deliver exceptional results.

It's time to move beyond just talking about risk and start actively mastering it together. As leading engineering consultants in Dubai, we have the hands-on expertise to navigate the unique challenges your project is guaranteed to face in this market.

We invite you to book a consultation with us to talk through your project's specific needs. Let's explore how a strategic partnership with FEC can provide the robust protection and peace of mind you need to succeed. Contact us today to secure your project's future.

Frequently Asked Questions

When it comes to construction in a market as fast-paced as Dubai's, having clear answers is crucial. We often get asked about the nitty-gritty of risk management, so we’ve put together a few of the most common questions we hear from our clients.

What Is the Single Biggest Risk for Dubai Projects Today?

That's a tough one, as every project has its own unique challenges. However, one risk that consistently rears its head is supply chain volatility. The sudden swings in the price and even the basic availability of materials, tangled up with global logistics problems, can completely derail a project’s budget and schedule.

The key is to not get caught off guard. A smart risk management strategy involves having a diverse list of suppliers, locking in prices with forward agreements when you can, and, most importantly, having a solid backup plan for your most critical materials. It’s about turning a potential disaster into a problem you already have a solution for.

How Early Should Risk Management Begin?

Right at the very beginning. We can't stress this enough. Risk management should kick off during the initial feasibility studies and concept design phase, long before any contracts are inked or designs are set in stone.

Why so early? Because identifying and planning for risks at this stage gives you the most leverage to mitigate them cheaply and effectively. Starting early is like building foresight directly into your project's DNA, preventing expensive headaches and disruptive changes down the line.

Is a Formal Risk Plan Necessary for Small Projects?

Absolutely. While you might scale down the complexity of the plan, the fundamental principles of managing risk apply to every project, regardless of size. On smaller jobs, things like an unreliable contractor, an unexpected permit delay, or a minor budget overrun can actually have a much bigger proportional impact.

Having a formal process, even a simplified one, forces you to think through what could go wrong and how you'll handle it. It's a simple step that protects your investment and dramatically improves the chances of a successful outcome, no matter how big or small the project is.

At Freeline Engineering Consultants, we do more than just point out risks; we build practical, robust strategies to neutralise them. Our deep-rooted local expertise and proven framework give your project the certainty it needs to succeed.

Ready to build with confidence? Contact us today to schedule your project consultation.